Institute of Chemistry has made a series of progresses in the controlled preparation and performance of graphene

The controllable synthesis of high-quality graphene is essential for both fundamental research and practical applications, making it a critical scientific challenge that demands in-depth exploration. This field involves precise control over parameters such as size, shape, grain boundaries, crystallinity, and doping to achieve tailored electrical properties.

Supported by the Chinese Academy of Sciences, the Ministry of Science and Technology, and the National Natural Science Foundation of China, researchers from the Organic Solids Laboratory at the Institute of Chemistry have made significant progress in controllable graphene preparation and performance optimization. Their findings have been published in top-tier journals like *Advanced Materials*, *NPG Asia Materials*, *J. Am. Chem. Soc.*, and *Nature Communications*.

One of the key challenges in graphene technology is the direct growth of graphene on dielectric layers rather than transferring it from metal substrates. Chemical vapor deposition (CVD) is widely used due to its ability to produce high-quality, large-area graphene. However, the transfer process often leads to defects, wrinkles, and contamination. Growing graphene directly on dielectrics offers compatibility with existing silicon-based electronics and simplifies device fabrication.

In previous studies, the lab developed an oxygen-assisted method to grow high-quality graphene directly on silicon dioxide, achieving controlled nucleation and crystal size. Later, they successfully grew large-area monocrystalline graphene on silicon nitride, demonstrating exceptional electrical performance with electron mobility reaching 1510 cm²/V·s in air and 1518 cm²/V·s in nitrogen—double that of conventional methods.

Another breakthrough involved the morphology regulation of single-crystal graphene. By controlling the CVD process, researchers created hexagonal graphene structures with sixfold symmetry, resembling snowflakes in nature. These structures revealed a universal growth mechanism governed by kinetic control, offering insights into the formation of two-dimensional atomic crystals.

Building on this, the team explored graphene etching behavior. They discovered that adjusting gas ratios during etching could lead to complex fractal patterns, challenging traditional notions of anisotropic etching. This work was featured in *J. Am. Chem. Soc.* and highlighted by *Chemistry World* as "carving graphene snowflakes with gases."

Additionally, researchers collaborated to create single-walled carbon nanotube/graphene junctions, which exhibited rectifying behavior and superior photodetection performance compared to conventional pn junctions. The results were published in *Nature Communications*.

These advancements not only deepen our understanding of non-equilibrium material growth but also open new avenues for scalable, high-quality graphene production. The studies highlight the interplay between order and disorder, simplicity and complexity, and provide valuable insights into both material science and natural phenomena.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

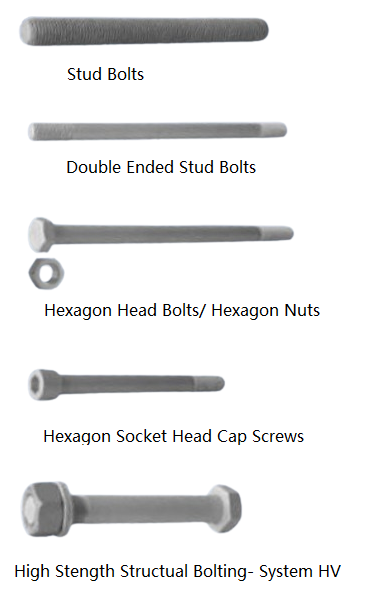

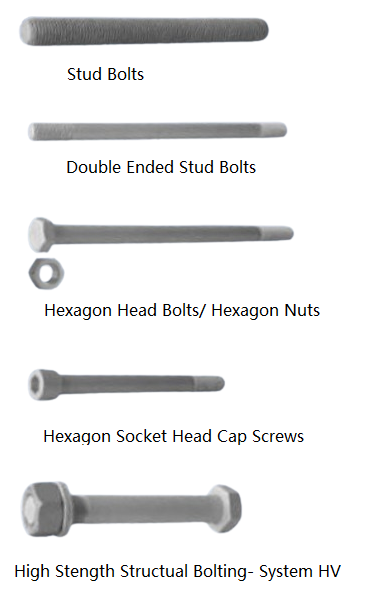

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com