The controllable synthesis of high-quality graphene is essential for both fundamental research and practical applications, making it a critical scientific challenge that requires further exploration. This field involves precise control over parameters such as size, morphology, crystal structure, doping, and boundary conditions to achieve desired electrical properties. Researchers have made significant progress in this area, supported by institutions like the Chinese Academy of Sciences, the Ministry of Science and Technology, and the National Natural Science Foundation of China.

Recent studies from the Organic Solids Laboratory at the Institute of Chemistry, Chinese Academy of Sciences, have focused on advancing the controllable preparation of graphene. Their work has led to breakthroughs in performance optimization and has been published in top-tier journals such as *Advanced Materials*, *NPG Asia Mater.*, *J. Am. Chem. Soc.*, and *Nat. Commun.*.

One major challenge in graphene production is the need to transfer it from its growth substrate to another dielectric layer for device fabrication. This process often causes damage, wrinkles, and contamination. To address this, researchers have developed methods to grow graphene directly on dielectric layers, making it compatible with existing silicon-based electronics and enabling direct device integration.

In earlier work, scientists introduced an oxygen-assisted chemical vapor deposition (CVD) method to grow high-quality graphene directly on silicon dioxide. They successfully controlled nucleation sites and crystallite size, achieving large-area monocrystalline graphene films. These films demonstrated exceptional electrical properties, with electron mobility reaching up to 1518 cm²/V·s in nitrogen, significantly higher than previously reported values.

Further research into the morphology and etching behavior of single-crystal graphene revealed fascinating patterns. By adjusting gas ratios during CVD, researchers observed a wide range of boundary structures, resembling natural snowflakes. This work, published in *Nature Materials*, established a universal growth mechanism governed by diffusion control, offering insights into the formation of two-dimensional atomic crystals.

Building on these findings, scientists explored graphene etching under different gas conditions. They discovered that etching can lead to complex fractal patterns, deviating from traditional anisotropic models. This discovery, featured in *J. Am. Chem. Soc.*, was highlighted by *Chemistry World* as "Carving graphene snowflakes with gases."

Additionally, researchers created single-walled carbon nanotube/graphene junctions, demonstrating rectification behavior and strong photodetection capabilities. These results, published in *Nat. Commun.*, suggest potential applications in advanced optoelectronic devices.

Overall, these studies highlight the complexity of graphene growth under non-equilibrium conditions and open new avenues for the development of high-quality, large-area, and environmentally friendly graphene materials. The findings also provide broader insights into material science, linking concepts like disorder, symmetry, and complexity to real-world phenomena.

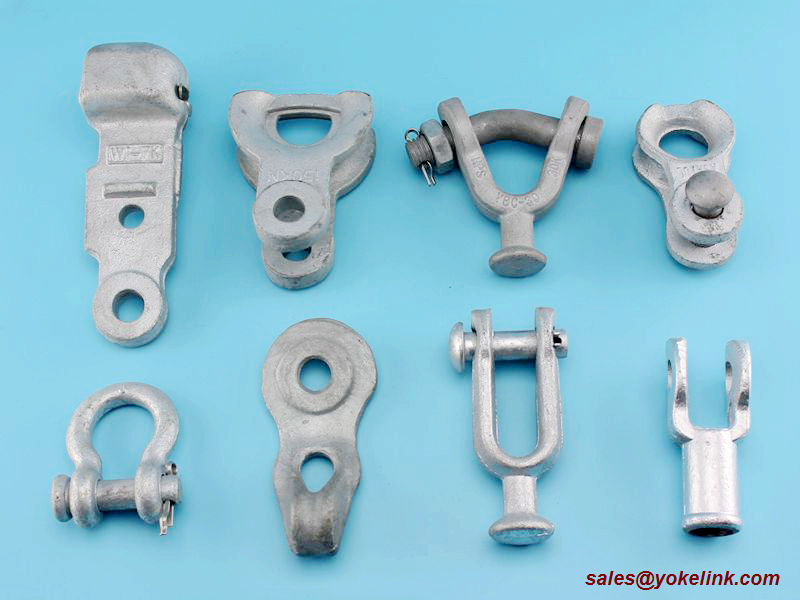

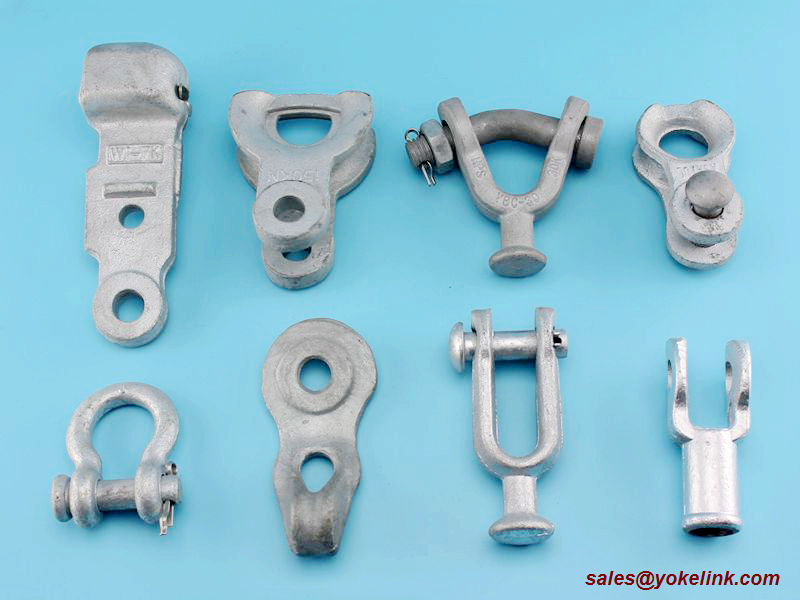

Transmission Hardware Fitting

Transmission hardware fittings are components used in the construction and maintenance of transmission lines for electricity or telecommunications. These fittings are designed to connect, support, and secure the different parts of the transmission line, ensuring proper functioning and reliability.

Some common types of transmission hardware fittings include:

Suspension Clamps: Used to hang the conductors from the transmission towers, providing support and preventing sagging.

Dead-end Clamps: Used to terminate the conductors at the ends of the transmission line, providing support and preventing them from slipping.

Splice Sleeves: Used to join two conductors together, ensuring a secure and conductive connection.

Insulators: Used to electrically isolate the conductors from the transmission towers, preventing electrical leakage and ensuring proper insulation.

Guy Wire Fittings: Used to secure and stabilize the transmission towers, preventing them from swaying or collapsing.

Connectors: Used to connect different components of the transmission line, such as conductors, insulators, and fittings, ensuring a secure and reliable connection.

Yokelink supply a full line of Tower hardwares, , provide part number to get a quote on these products, leave your message, or send us an email to get answers for your questions or product you needed.

Socket Eyes are used for connecting conductor clamping devices to ball and socket type insulators. Made by malleable iron, hot dip galvanized to meet ASTM A153 specification.

Ball Eyes are used to attach ball and socket insulators to other associated hardware. Hot dip galvanized to meet ASTM A153 specification.

Thimble Cleivs are used for attaching guy to pole eye plate. Hot dip galvanized to meet ASTM A153 specification.

Turnbuckles are used as adjustable extension links to maintain proper tower clearance on assemblies at tower end.

Strain Clamp used for distribution and transmission line construction with all aluminum ACSR, or aluminum alloy conductor.

Transmission Hardware Fitting, Socket,Ball eye, Hot line, Chain Link, Turnbuckle, Suspension, Strain, Yoke plate,malleable iron,hardware,tower,links

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com