Three Causes of Blackening Copper Wires in Rubber Jackets

**Rubber-Sheathed Cables and the Issue of Copper Wire Blackening**

A **rubber-sheathed cable** is a type of flexible, movable cable that uses multiple fine copper strands as its conductor, surrounded by rubber insulation and a protective rubber sheath. These cables are commonly used in various applications such as general flexible cables, welding machine cables, submersible motor cables, radio equipment cables, and photographic lighting cables.

One of the most common issues with these cables is the **blackening of the copper wire**, which can occur due to a variety of factors. It's not just about the rubber formulation, but also the condition of the copper itself, the processing techniques used, the vulcanization process, the overall cable structure, environmental conditions during production, and more.

### 1. Causes of Copper Wire Blackening

#### 1.1 The Role of Copper Material

In the 1950s and 1960s, most manufacturers used standard copper rods with a purity of 99.99%, which were aerobic copper. These rods were processed through multi-channel heating and rolling, resulting in blackened copper rods. After further drawing, thin copper wires were produced. Since these were not oxygen-free copper, oxidation was inevitable during processing.

By the 1980s, the use of oxygen-free copper rods became widespread, significantly reducing the problem of blackened copper wires. However, even with this improvement, improper processing or storage of the copper cores could still lead to minor oxidation, contributing to the blackening issue.

#### 1.2 Impact of Rubber Formulation

Early rubber formulations often used natural rubber and styrene-butadiene rubber. Due to the direct contact between the rubber and copper, sulfur could not be used directly as a vulcanizing agent, leading to less sulfur being used. This sometimes caused copper wire discoloration.

To compensate, accelerators like TMTD and vulcanizing agents like VA-7 were added. However, these compounds could release free sulfur, which reacts with copper, causing it to darken. Additionally, fillers like calcium carbonate and talcum powder, if not properly treated, could contribute to the problem. Some manufacturers used low-quality fillers, which had large particles and impurities, leading to poor electrical properties and increased risk of copper discoloration.

Moreover, certain accelerators, like ZDC, can indirectly affect copper by forming sulfide compounds, which may not immediately cause blackening but can do so over time.

### 2. Structural Factors in Cable Design

#### 2.1 Copper Catalytic Aging

Copper can penetrate into the insulating rubber during vulcanization, acting as a catalyst for aging. Even small amounts of copper can degrade rubber over time, leading to stickiness and other performance issues. This effect is particularly noticeable when heavy metals like copper or manganese are present in the rubber.

#### 2.2 Sulfur Migration

Sulfur from the rubber sheath can migrate toward the insulating layer and copper wire, especially under high temperatures. This migration leads to the formation of copper sulfides, which not only cause discoloration but also accelerate rubber aging, resulting in stickiness and reduced performance.

### 3. Processing and Vulcanization Issues

#### 3.1 Rubber Processing Problems

During the plasticization of natural rubber, improper temperature control can cause excessive breakdown of rubber molecules, leading to a lower molecular weight and increased stickiness. If the vulcanizing agents are not evenly distributed, localized areas may have too much sulfur, leading to blackened copper wires.

#### 3.2 Inadequate Vulcanization

Some companies use short vulcanization tubes and high-speed production lines, which result in insufficient vulcanization. This can leave excess free sulfur in the rubber, which then reacts with copper, causing it to darken. Excessive use of accelerators like TMTD can also contribute to this issue.

### Conclusion

The problem of copper wire blackening in rubber-sheathed cables is complex and involves multiple factors. From the quality of the copper wire to the rubber formulation, processing methods, and vulcanization techniques—every step must be carefully controlled. While some solutions have been developed, the challenge remains ongoing. Solving this issue requires continuous research, testing, and refinement of materials and processes. Only through careful attention to detail at every stage can we achieve long-term success in preventing copper wire discoloration.

.

.

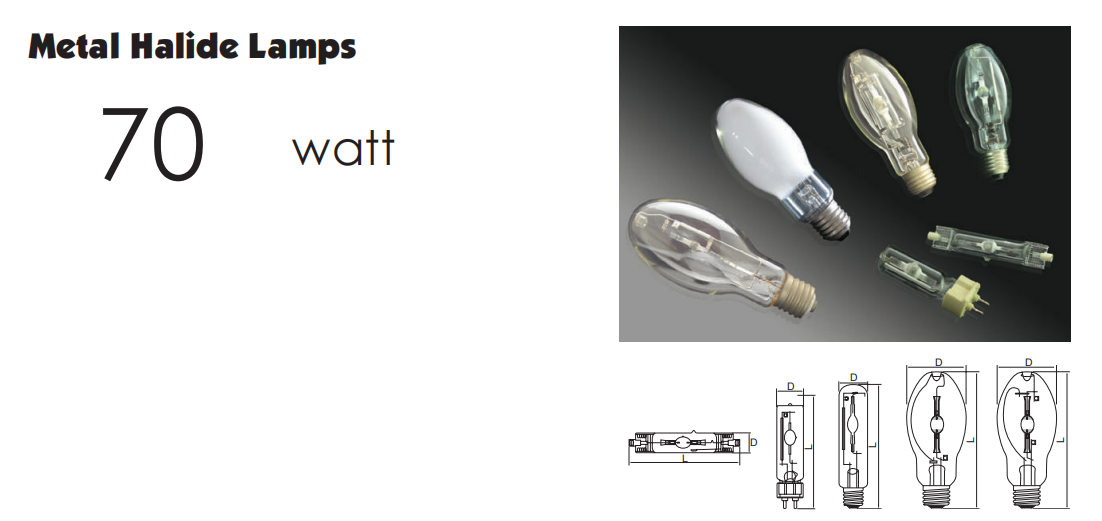

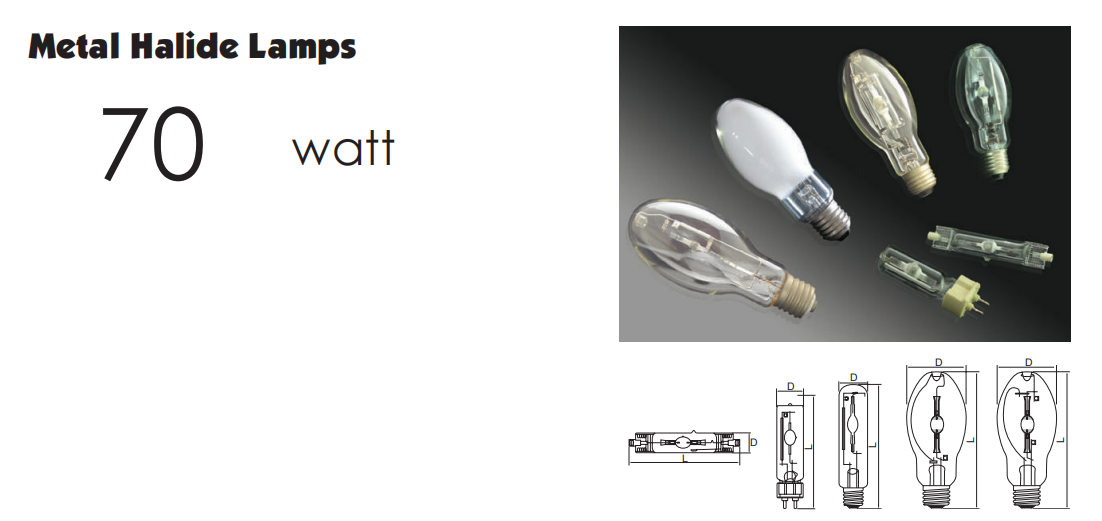

Metal Halide Bulb

A Metal Halide Bulb, also known as a Metal Halide Lamp, is a type of gas discharge lamp that produces light by passing electrical currents through a mixture of mercury and metal halides. It is known for its high luminous efficacy, long lifespan, and good color rendering index, making it a popular choice for various industrial and commercial applications

4

Key Features

- High Luminous Efficacy: Achieves light efficacy ranging from 65 to 140 lm/W.

- Long Lifespan: Typically lasts between 5000 to 20,000 hours.

- Good Color Rendering: Provides a high color rendering index (Ra) of 65 to 95, offering accurate color representation.

- Compact and Stable Design: Available in quartz and ceramic versions, offering structural stability and durability.

Applications

Metal Halide Bulbs are widely used in:

- Stadiums and Sports Arenas: For their high output and ability to provide optimal lighting conditions.

- Construction Sites: Ensuring safety and visibility during nighttime operations.

- Parking Lots and Loading Docks: Providing bright, consistent lighting for extended periods.

- Commercial Buildings: Enhancing the aesthetic appeal and functionality of indoor spaces

.7

metal halide bulb,400 watt metal halide bulb,250 watt metal halide bulb,1000 watt bulb,100 watt metal halide bulb

Yangzhou M.T. New Energy & Lighting Group Co., Ltd. , https://www.mtstreetlight.com